The Single Strategy To Use For Premier Aluminum Llc

The Single Strategy To Use For Premier Aluminum Llc

Blog Article

6 Easy Facts About Premier Aluminum Llc Explained

Table of ContentsEverything about Premier Aluminum Llc6 Easy Facts About Premier Aluminum Llc DescribedRumored Buzz on Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum LlcThe Greatest Guide To Premier Aluminum Llc

When selecting a light weight aluminum shop for your production needs, it's essential to study a number of aspects. One of one of the most critical facets to take into consideration is the experience and capability of the foundry. Choosing a foundry who has the ideal understanding of the light weight aluminum spreading procedure, and the profile to reveal for it, assists to have an effective result for your job.Having the experience and sector knowledge to engineer your spreadings for optimal production and quality results will enhance the task. Making light weight aluminum castings needs a complicated set of processes to achieve the right outcomes. When deciding on a brand-new aluminum foundry to companion with, guarantee they have extensive sector experience and are educated concerning all facets of the light weight aluminum spreading procedure: design, production, product evaluation, and product testing.

The foundry needs to additionally have a tried and tested track document of providing phenomenal items that satisfy or exceed consumer assumptions. Quality control should additionally be at the top of your checklist when selecting an aluminum shop. By dealing with a qualified shop that follows the standards for high quality control, you can protect the honesty of your product and ensure it fulfills your requirements.

Examine This Report about Premier Aluminum Llc

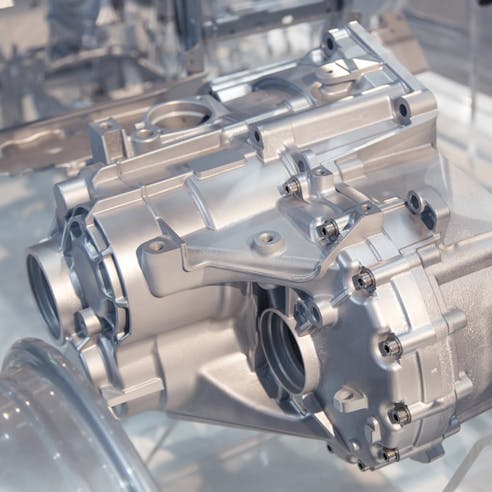

Different parts that really made complex shapes can be made utilizing this process. Before you begin searching for a trusted aluminum pass away caster, there are some vital points that you need to do.

You have to ask yourself what kind of aluminum pass away castings you call for. After identifying what you call for, you have to specify the specs of the light weight aluminum die spreadings you need. Identify the weight, thickness, size, and other specs of the light weight aluminum die-cast you call for. It would likewise be much far better if you can draw and reveal all the measurements of the light weight aluminum die-cast.

Do you understand just how much money you need to invest in the items? In order to do this, the very best point to do is to figure out the amount of light weight aluminum diecasts you call for. After having this details, you can begin researching light weight aluminum die-casting producers. You can do this by merely keying the keyword" Aluminum die casting producers" on the Google online search engine.

Several of the questions you need to ask yourself are whether they have actually experienced and well-trained drivers, for how long their business has functioned, or if they have some success. You can often obtain the answers to these concerns from the manufacturer's web site. You can look into other internet sites or exterior sources to verify if the info supplied on the manufacturer's site is genuine.

10 Easy Facts About Premier Aluminum Llc Shown

One more thing you have to consider is the producer's capacity to generate aluminum die-casting products. In other words, the volume of items the maker can create at an offered time. A few of the critical inquiries you need to ask yourself are whether the manufacturer can produce a greater quantity or can the supplier meet your demands.

(https://www.pubpub.org/user/gary-martin)What if your business needs 10,000 pieces of specific device components from the manufacturer within one month? You got this amount; nevertheless, the manufacturer can just produce 5000 items of these maker components within one month (Foundry). Because of this, you won't be able to obtain the amount that you purchase promptly

The Only Guide for Premier Aluminum Llc

For this reason, it is very important that you should inquire if the manufacturer is implementing an in-house tooling process. In addition, you need to ask the manufacturer how much the cost of internal check that tooling is. The in-house tooling procedure, which allows you to produce distinct layouts and shapes can be an additional price.

This facet directly associates with the manufacturer's production capacity. Foundries in Wisconsin. You have to look for a maker that can ensure quicker shipment of items.

This implies that there are numerous options that you can select from. Today, customer demands continue changing. It seems that clients are looking for an exceptional mix of quality, cost-effectiveness, and durability. That is why it is considerably recommended that you must select a maker that can create different sorts of light weight aluminum die-cast items.

Getting My Premier Aluminum Llc To Work

Frequently, these light weight aluminum die-casting items will need some designs, machining, or completing touches. Having this in mind, you ought to search for a producer that can perform a selection of second ending up jobs when die casting is done. Some instances of ending up operations include Chromating, CNC Machining, Sandblasting, Powder finishing, Anodized, E-coating, Wet paint, Plating, and much more.

Die spreading is just one of the most affordable, accurate, and protean production processes worldwide moment. The process entails suitable molten significance, under pressure, right into an applicable die (earth), and formerly solidified it can be ejected and finished (if necessary) in a selection of means. The passes away are [...]. Report this page